Services

Lubrication System in Power Transformers

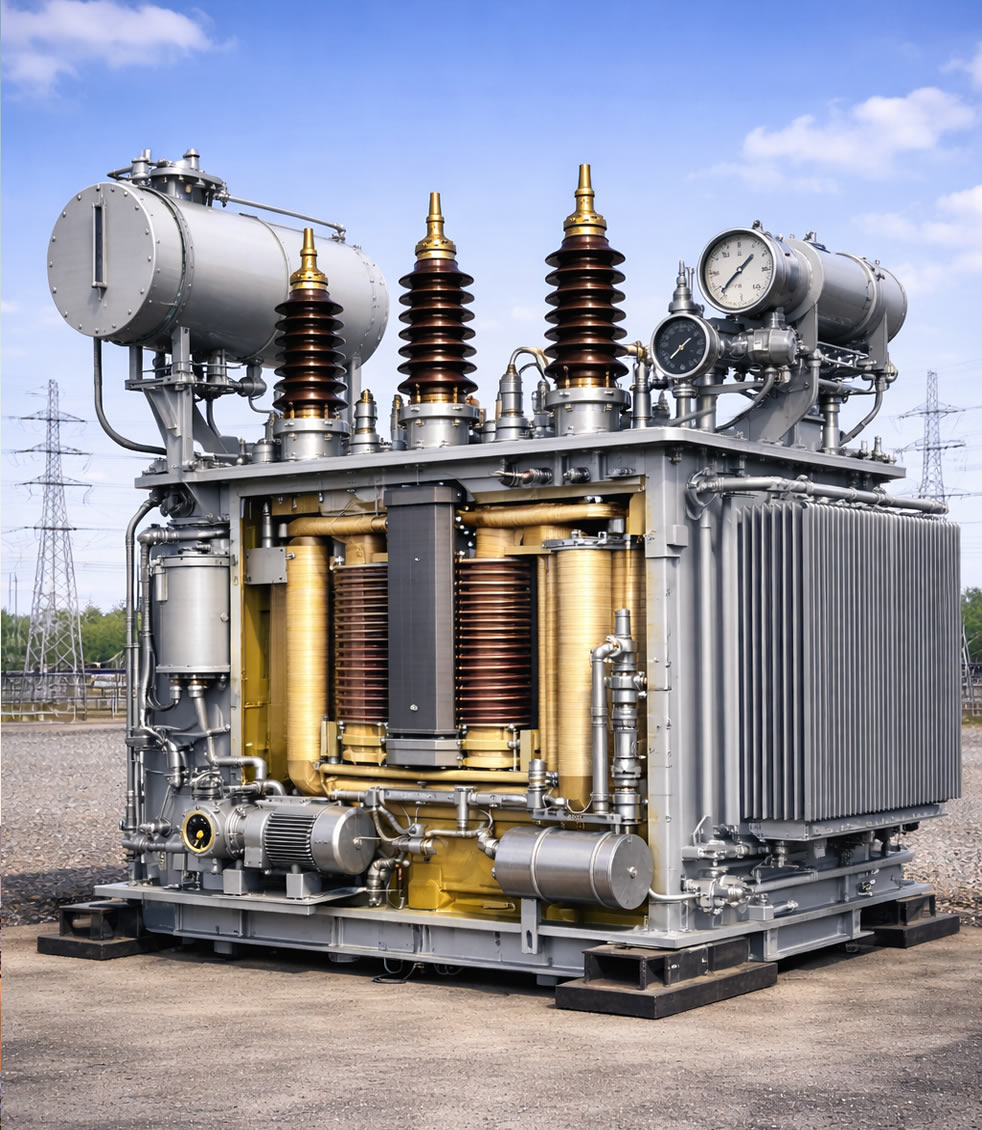

In power transformers, the lubrication system refers primarily to the insulating oil system, which performs four critical functions:

- Electrical insulation

- Cooling (heat transfer)

- Lubrication of moving parts (tap changers, pumps, valves)

- Arc quenching (especially in On-Load Tap Changers – OLTCs)

Any degradation in oil quality directly affects transformer performance and lifespan.

Some of the Major Challenges Faced by Transformer Lubrication (Oil) Systems

- Oil Contamination

- Moisture Absorption

- Oxidation and Oil Aging

- Sludge Formation

- Degradation of Lubrication Properties (OLTC)

Overall, poor oil health directly reduces transformer productivity by limiting load capacity and increasing downtime.

Remedies: Ways and Methods to Address These Challenges

- Oil Filtration and Purification

- Breather Maintenance

- Oil Reconditioning and Reclamation

- Regular Oil Testing and Monitoring

Best Practices for Power Transformer Oil Care is to Implement condition-based maintenance (CBM), proper Oil Handling and Storage, Use of Inhibited Oils, Maintain Proper Oil Temperature.

The lubrication (oil) system is the lifeline of a power transformer. Challenges such as contamination, moisture ingress, oxidation, sludge formation, and circulation failures directly compromise reliability, productivity, and safety. Through robust monitoring, preventive maintenance, oil purification, and adherence to best practices, transformer oil life can be significantly extended, ensuring high availability and long service life of power transformers.